When it comes to soap making there are important safety considerations to keep in mind, especially when it comes to listing ingredients. One common question that soap makers often ask is whether or not lye, a key component in the soap making process, needs to be listed as an ingredient in the final product.

Lye doesn’t need to be listed as an ingredient in soap because it is not present in the final product. Through the saponification process, lye is used to create the soap, but it is entirely consumed and transformed into soap molecules, leaving no trace in the final product.

This means that it is not a necessary ingredient to list, however, some soap makers choose to include a disclaimer about the use of lye in the product. Including this disclaimer can be beneficial as it serves to inform consumers about the process used to make their soap.

Why Lye Doesn’t Have To Be Listed

Lye Dissolves During Saponification

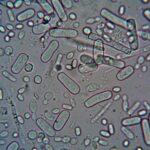

When making soap, lye is mixed with fats and oils, which causes a chemical reaction called saponification. This reaction turns the lye and fats into soap and glycerin. As a result, the lye is no longer present in the finished product and has been transformed into soap. Some soapmakers argue that because the lye is no longer present, it should not be listed as an ingredient.

It Isn’t Legally Required

Under current FDA regulations, lye does not need to be listed as an ingredient on soap labels.

According to the FDA, soap is considered its own category of product and is regulated differently than other cosmetic products. Soap is not required to list all of its ingredients, but rather is required to list only the ingredients that make up the soap itself. This means that the lye used to make the soap is not required to be listed separately.

While some soapmakers choose to include it for transparency purposes, others argue that it is not required and therefore should not be listed.

Soap Labeling Regulations

Here are the three labeling requirements that must be met when selling soap.

Product Identity

The first requirement is to identify the product. This means that the label must clearly state that the product is soap. The name of the soap should also be included on the label. For example, if your soap is lavender scented, the label should read “Lavender Scented Soap”. This requirement ensures that customers know exactly what they are purchasing.

Net Quantity of Contents

The second requirement is to indicate the net quantity of contents of the soap. This means that you must state how much soap is in the package. The weight of the soap must be listed in ounces, pounds, or grams. This requirement ensures that customers are getting what they paid for.

Manufacturer’s Information

The third requirement is to include the manufacturer’s information on the label. This means that you must provide your name, address, and contact information on the label. This requirement ensures that customers know who to contact in case of any issues or concerns with the soap.

It is important to note that the regulations on soap labeling may vary depending on the country or state. In the United States, the Food and Drug Administration (FDA) regulates soap labeling.

Common Soap Making Misconceptions

Here are three common misconceptions about soapmaking and set the record straight.

Pre-saponification ingredients must be listed

One common misconception about soapmaking is that all ingredients used in the soap must be listed on the packaging. This is not entirely true. Only the ingredients that remain in the finished soap after saponification need to be listed.

Saponification is the process by which oils and fats are combined with an alkali (usually lye) to create soap. During this process, the oils and fats are broken down and combined with the alkali to form soap molecules.

Any excess alkali is neutralized and becomes a part of the soap. This means that the alkali used in soapmaking (usually sodium hydroxide or potassium hydroxide) is no longer present in the final product and does not need to be listed on the packaging.

However, any pre-saponification ingredients, such as fragrance oils, colorants, and botanicals, should be listed on the packaging. These ingredients can affect the scent, color, and texture of the soap and may be of concern to those with allergies or sensitivities.

Beliefs about lye being a harmful ingredient

Another common misconception about soapmaking is that lye is a harmful ingredient that should be avoided. While it is true that lye is a caustic substance that can cause skin irritation and burns if not handled properly, it is an essential ingredient in soapmaking.

Without lye, there would be no chemical reaction to turn the oils and fats into soap. In fact, all soap, whether handmade or commercially produced, is made using lye.

It’s important to note that when lye is mixed with water and oils/fats, a chemical reaction occurs that converts the lye into soap molecules. This means that the final product contains no residual lye and is safe to use.

Soapmakers take great care to ensure that the correct amount of lye is used in their recipes and that the lye is completely neutralized during the saponification process. This ensures that the final product is safe for use.

The truth about lye in soap and its safety

So, what is the truth about lye in soap? Lye is a necessary ingredient in soapmaking, but it must be handled with care. Soapmakers should wear gloves and eye protection when working with lye and ensure that their work area is well-ventilated.

It’s also important to use accurate measurements and follow recipes carefully to ensure that the correct amount of lye is used.

Once the soap has been made and cured, there is no residual lye left in the soap. The saponification process ensures that the lye has been converted into soap molecules, making the final product safe for use.

Checking Finished Soap For Undissolved Lye

Here are some steps to check for undissolved lye in completed soap:

- Wait for the soap to cure: After making soap, it needs to cure for several weeks to allow the saponification process to complete fully. Once the soap has cured, you can begin to check for undissolved lye.

- Wet the soap: Wet the soap with warm water and rub it between your hands to create a lather.

- Touch the lather: Touch the lather to your tongue. This may sound unusual, but lye has a distinctive taste, and if there is any undissolved lye in the soap, you will be able to taste it. Be sure to rinse your mouth thoroughly afterward.

- Look for signs of lye: If you don’t want to taste the soap, you can also look for signs of undissolved lye. These may include a gritty texture or tiny white specks in the soap. If you see or feel either of these, it’s best to discard the soap and start again.

- Test the pH: Another way to check for undissolved lye is to test the pH of the soap. To do this, you will need pH test strips, which are available at most health food stores. Wet the soap and rub it onto a strip, then compare the color to the pH chart provided. The pH of cured soap should be between 7 and 10. If the pH is higher, there may be undissolved lye in the soap.

Frequently Asked Questions

Lye is highly caustic and can cause severe chemical burns if not handled properly. It can also produce dangerous fumes and should be used in a well-ventilated area.

No, lye is an essential ingredient in soap making, as it is needed to transform oils and fats into soap through saponification.

When used properly and in the correct proportions, lye in soap is safe. Through the saponification process, the lye is entirely consumed and transformed into soap molecules, leaving no trace in the final product.

Lye should be measured by weight, using a digital kitchen scale for accuracy.

No, lye cannot be substituted in soap making. Other substances, such as baking soda or vinegar, may be used in other cleaning products but will not produce soap through saponification.

If too much lye is used in soap making, the resulting soap can be too harsh and irritating to the skin.

If not enough lye is used in soap making, the soap may be too oily or may not solidify properly.

Conclusion

In conclusion, lye does not need to be included in an ingredient list. With the right safety precautions and accurate measurements, you can create beautiful soaps at home without worrying about leaving any residual lye in your finished product.

Remember, you can always test for undissolved lye after curing your soap if you are uncertain – either by tasting or testing its pH levels – before using it on yourself or selling it commercially. Soapmaking may seem like a complicated craft, but if done correctly and safely, you’ll find that making handmade soaps can be both rewarding and fun!